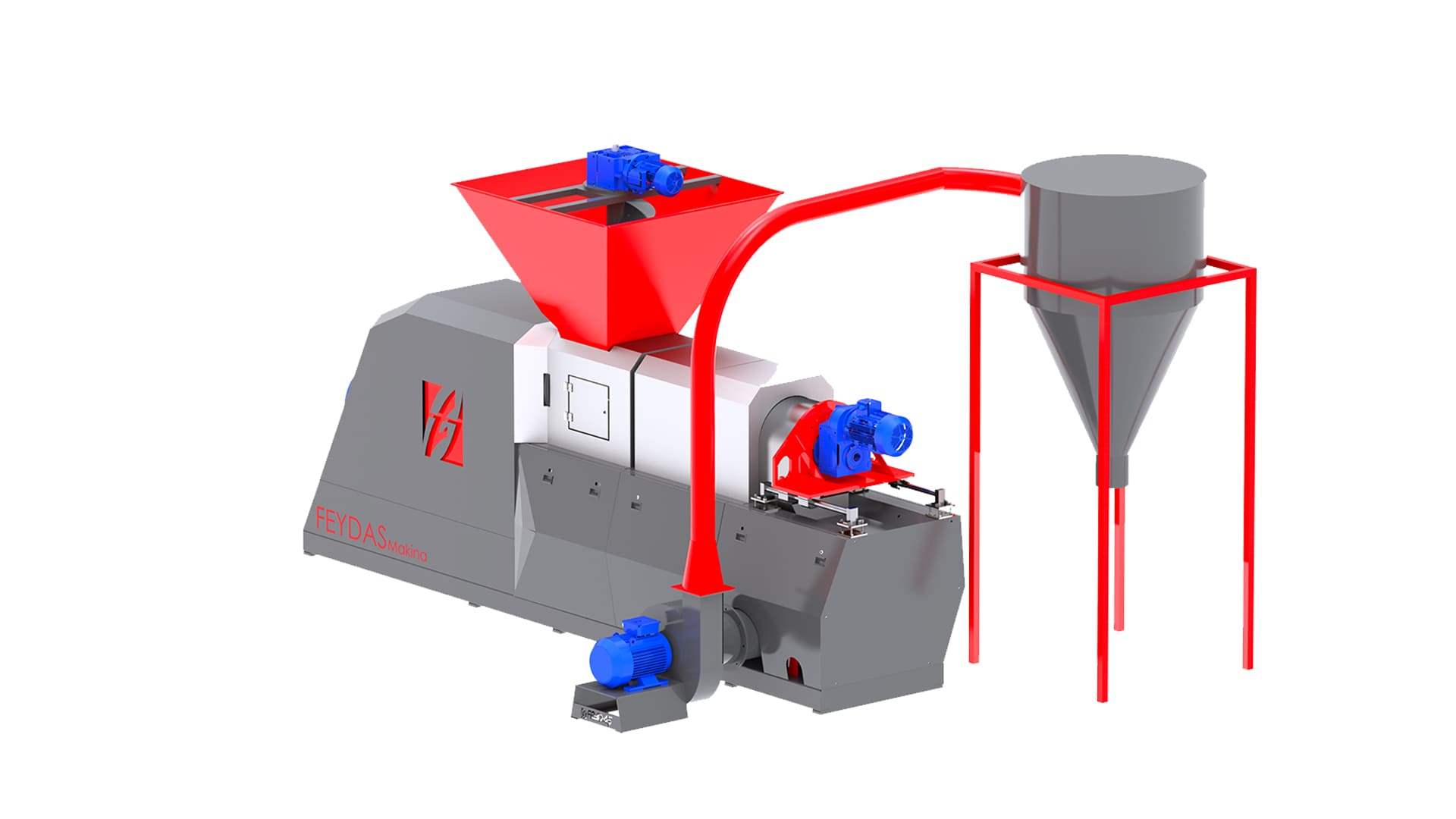

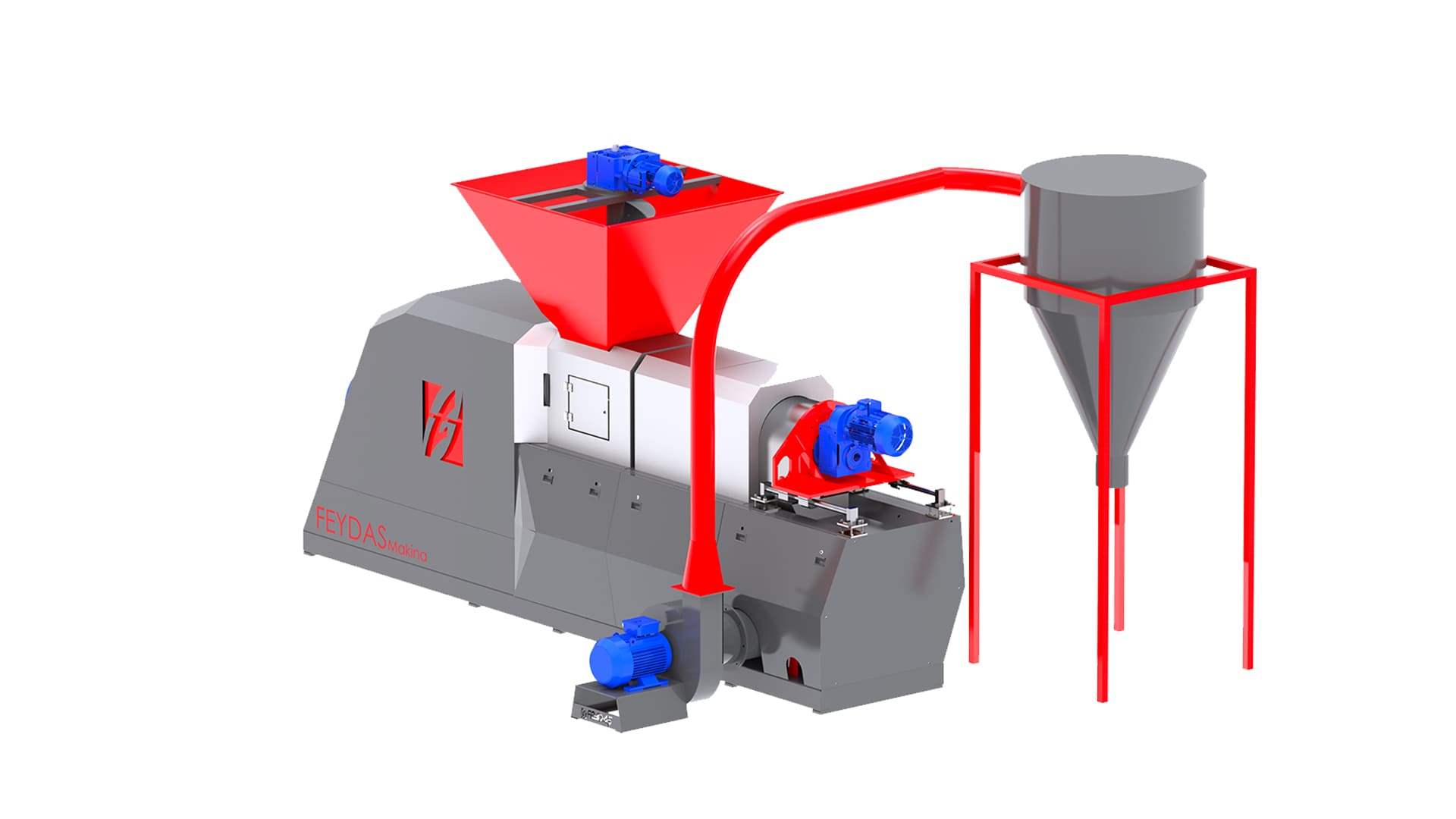

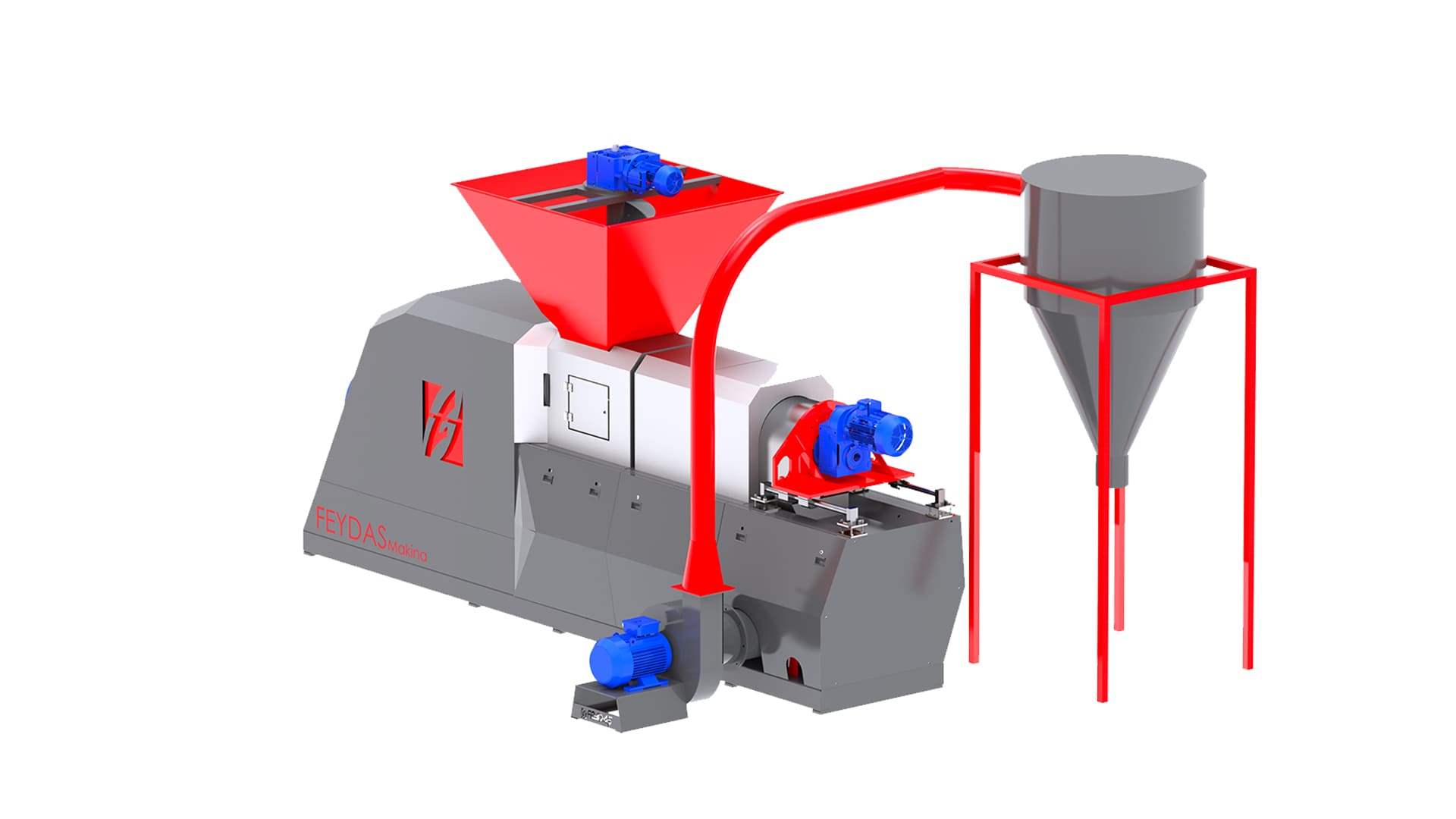

SQUEEZING & DRYING MACHINE

SQUEEZING & DRYING MACHINE

SQUEEZING & DRYING MACHINE

The humidity of the material coming out of the drying-squeezing is less than 3%. Operates automatically, saves manpower cost & electricity cost by 30%. Squeezed and dried material is sent directly to extruder to become granules. Operating 365 days / 24 hours, it increases the capacity, reduces maintenance cost. The feeded recycled materials are squeezed to become flakes or lumps. After being squeezed, these lumps or flakes with much lower moisture and higher density can be directly fed into pelletizing extruder. 1 Feydaş' single screw squeezer saves cost, energy and time. It helps to protect environment and increase productivity as well as efficiency.

Drying Juicing Machine Details

| MACHINE DETAILS | PHOENIX 300 | PHOENIX 300 GAZ ALMALI-DEGASSING | PHOENIX 500 |

|---|---|---|---|

| MAIN ENGINE POWER | 90-110 KW | 90-110 KW | 160-200 KW |

| SCREW DIAMETER | 300 MM | 300 MM | 500 MM |

| MACHINE LENGTH | 3500 MM | 4000 MM | 4500 MM |

| MACHINE HEIGHT | 2500 MM | 2500 MM | 2500 MM |

| MACHINE WIDTH | 1200 MM | 1200 MM | 1400 MM |

| CAPACITY | 500-600 KG/H | 600-1000 KG/H | 800-1300 KG/H |

| HUMIDITY | % 0-3 | % 0-3 | % 0-4 |

| BLOWER MOTOR POWER | 7,5 KW | 7,5 KW | 11 KW |

| SILO DIAMETER | 1000 MM | 1000 MM | 1000 MM |

| BLADE MOTOR POWER | 4 KW | 4 KW | 5,5 KW |