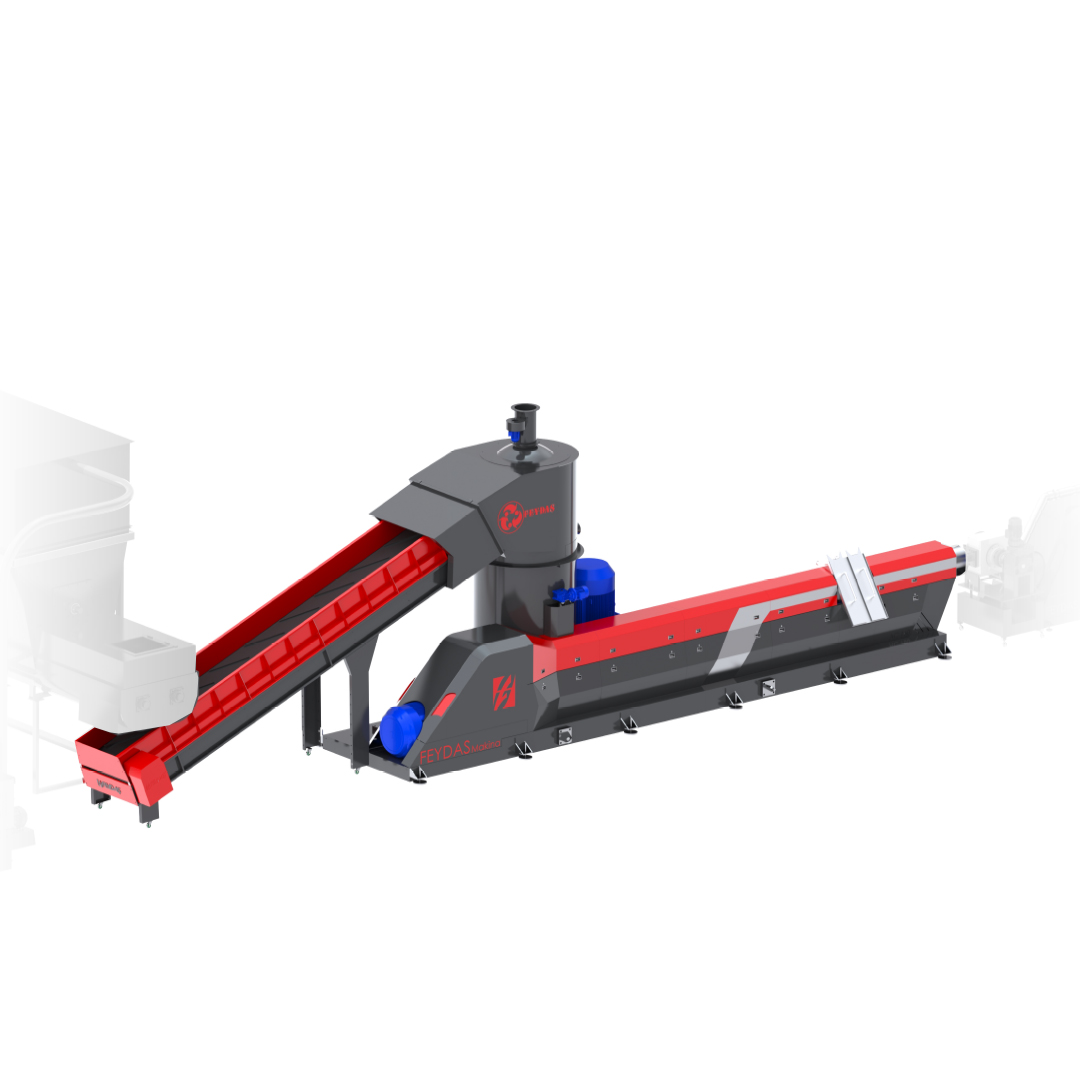

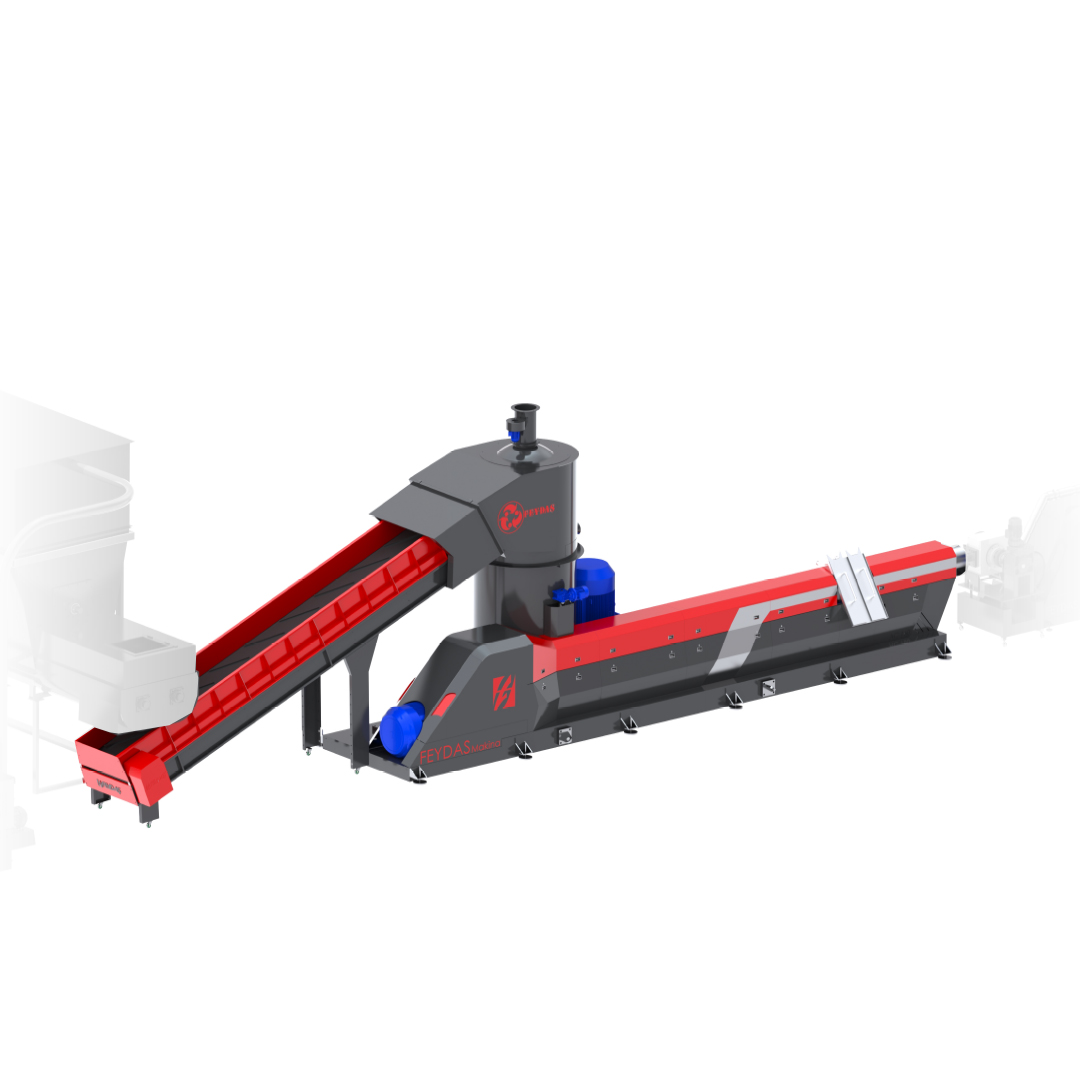

Agglomerated Granule Machine

The agglomerated granule machine is designed to granulate at high capacity and efficiency to crush, mix, dry and condense the waste plastics, to be recycled, by feeding the extruder screw at required performance.

Working Principle:

Plastic scrap is crushed in the tank with rotating blades. Specially designed guides provide more compression of plastic scrap. With this process, humidity in the plastic is removed. The crushed and heated final product becomes ready for the extruder.

Extruder:

Thanks to the special screw design, it makes easier compression and better melting of the material coming from the cutting tank. It is a machinery group that manufactures quality, smooth granular raw materials thanks to its vacuum system and screw design for making humid and gas products gas-free.

Agglomerated Granule Machine Details

| MODEL | DOLPHIN-100 | DOLPHIN-120 | DOLPHIN-130 | DOLPHIN-140 | DOLPHIN-160 | DOLPHIN-180 | DOLPHIN-200 |

|---|---|---|---|---|---|---|---|

| SCREW L/D | 40/1 | 40/1 | 40/1 | 40/1 | 40/1 | 42/1 | 42/1 |

| EXTRUDER MOTOR POWER | 110 KW | 160 KW | 160 KW | 200 KW | 315 KW | 315 KW | 315 KW |

| AGGLOMERATION MOTOR POWER | 90 KW | 110 KW | 132 KW | 200 KW | 250 KW | 250 KW | 250 KW |

| CAPACITY | 250-300 KG/H | 400-600 KG/H | 600-800 KG/H | 700-900 KG/H | 900-1250 KG/H | 1250-1500 KG/H | 1500-1800 KG/H |